Cold roll forming machine foundation, sometimes called the roll forming machine mill, support the components needed for the shaft brake, roller, drive chain, and other molding structures.

The most important requirement of the bed is.

- The operator transports the rigidity during installation.

- The flatness and levelness of the upper surface of the mounting assembly.

- Keyway or other location for rack positioning.

- Drainage equipment for cold bending lubrication.

A long roll forming machine mill is divided into two or more parts. To be used for processing, handling, and transportation.

There is no standard machine mill design, but most machine mills are similar in structure, and the inapplicable version is made with a straight tube section.

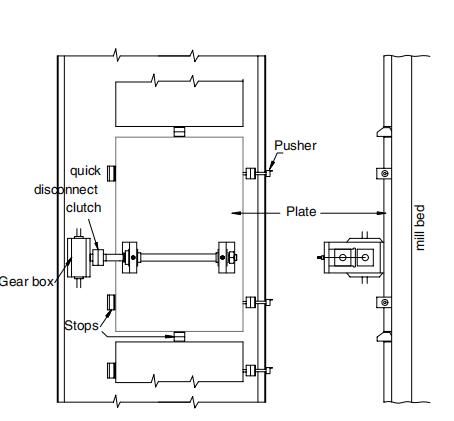

The following figure shows a typical machine mill structure.

The upper surface of the top plate can be machined entirely or machined longitudinally only at the mounting position of the frame and gearbox. The positioning keyway must be nailed to the full length of the plate. The full linear length of the keyway shall be within 0.05 mm. The machine mill shall be drilled and tapped one piece, and the frame and other components shall be installed. The base color album is welded to the frame structure fixed on the lower side of the top plate of the lathe bed, and the horizontal plate and the base plate are fixed with the frame.

Cross plates and other components are welded to such foundation frames to increase rigidity and bracing. Motor bearing drive chain support to be considered in addition.

In most cases, the technical height of the machine mill is such as to provide a comfortable presentation height. Usually, the height of the roll forming machine mill is set up from 900 to 1025 mm. In order to obtain a comfortable presentation height, a pressure-reducing press or other equipment can also be installed in the pit.

Post time: 06-20-2020