Three layer roll forming machine

Short Description:

1.Description of Three layer roll forming machine To save space, some customer like double layer or three layer machine, sure it will also save some money for customer. Common compared with two single machine, double layer roll forming machine save one bottom frame, one control box, one motor (while motor need increase power than one single machine) Do you know that: Two layer of double layer machine can not work at same time, For example, up layer working, down layer can not work, and if u w...

Product Detail

FAQ

Product Tags

1.Description of Three layer roll forming machine

To save space, some customer like double layer or three layer machine, sure it will also save some money for customer.

Common compared with two single machine, double layer roll forming machine save one bottom frame, one control box, one motor (while motor need increase power than one single machine)

Do you know that: Two layer of double layer machine can not work at same time, For example, up layer working, down layer can not work, and if u want down layer work, up layer can not work.

If down layer meet problem, u need take up layer roller station out, than fix the down layer problem, are u sure u can settle down it?

As ur like and request to choose double layer machine or three layer machine or single layer machine.

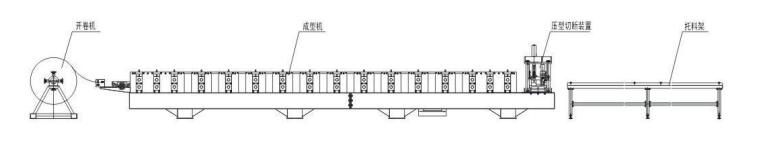

2.Working process

The complete line includes decoiler, forming machine, computer controlling system and run out tables. Our machines are equipped with a computer controlling system to keep products accurate.

3.Diameter of Three layer roll forming machine

|

NO |

Type |

Specification | |

|

1 |

Raw material | Type | PPGI |

| Feeding width | 1250 mm | ||

| Thickness | 0.3-0.8 mm | ||

|

2 |

Decoiler | Operation | Manual |

| Weight apacity | 5 Tons | ||

|

3 |

Main body | Roller station | 15/11 row |

| Diameter of shaft | 70 mm | ||

| Shaft material | 45# with 0.05mm chrome | ||

| Roller material | 45# with 0.05mm chrome | ||

| Type | Chinese type | ||

| Frame | 300mm H-beam | ||

| Frame thickness | 20 mm | ||

| Material | Cr 12 | ||

| Operation | Hydraulic automatic | ||

| Working speed | 8-12 m/min | ||

|

4 |

Power | Driving way | Chain 1 inch |

| Main motor | 7.5 KW | ||

| Voltage | 380V/50HZ, 3 phase | ||

|

5 |

Control box | Electric box | PLC control system, inventer |

| PLC brand | Delta made in Taiwan | ||

| Inverter brand | Delta made in Taiwan | ||

| Language | Chinese and English | ||

1 Q: Are you a manufacturer?

A:Yes, we are manufacture with four branches factory

2. Q: How to order my machine

A: Send me your design drawing if you have.

Or tell me your design idea. Our engineer will design it as your needs.

3. Q: What details of the machine you should get from me.

A: I will confirm all details with you, such as the voltage in your city.

4. Q: I am new in this field. How could i understand the machine very well

A: Contact with us,24 hours online service side.

5. Q: I receive a lot of quotations, they are big difference, How could i choose?

A:we have many easy ways to solve it. Fox example, we can teach you how to find the Traders out. Just contact us.

6.Q: Can you give me one suggestion for ordering the machine.

A: No problem. Do not trust your eyes when you see beautiful pictures of machines or factories. More when you contact.

7. Q: Can you use other brand of spare parts for me if i want.

A: No problem if you want to pay the money.