1.5mm slitting machine line with high quality

Short Description:

Description of 2000mm width 1.5mm thickness slitting machine with high quality Automatic steel coil piece to piece sheet cutting machine line is using in wholesale sheet business. We use this machine to cut to pieces and sell them to client. This cutting machine can cut length one by one. There are up 5 and down 6 stations for flatten the material which make coil straightly input to cutting machine. It is using for bring the steel coil running and do not break the surface of steel coil. ...

Product Detail

FAQ

Product Tags

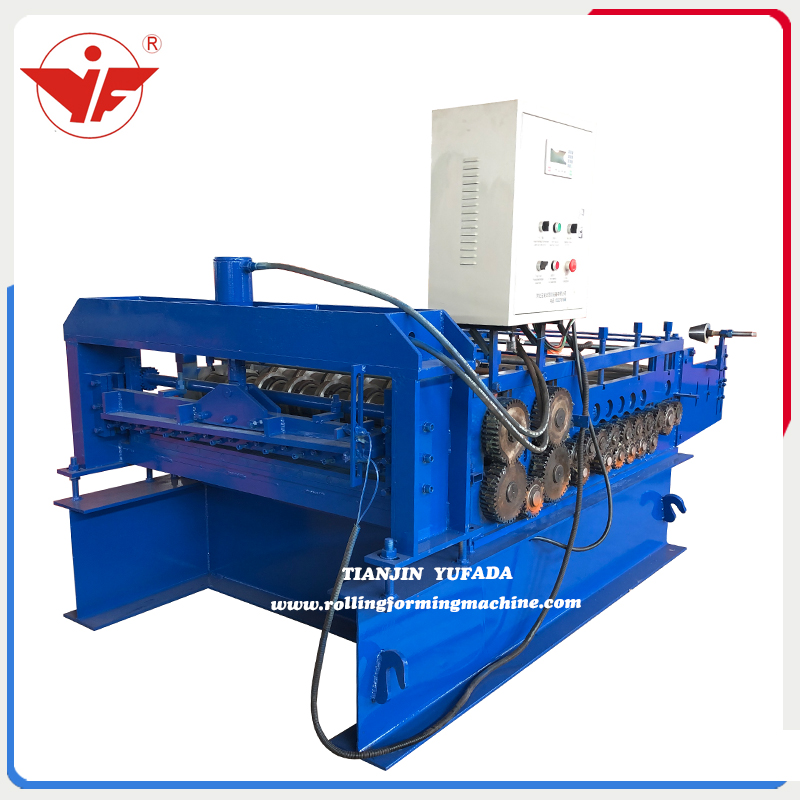

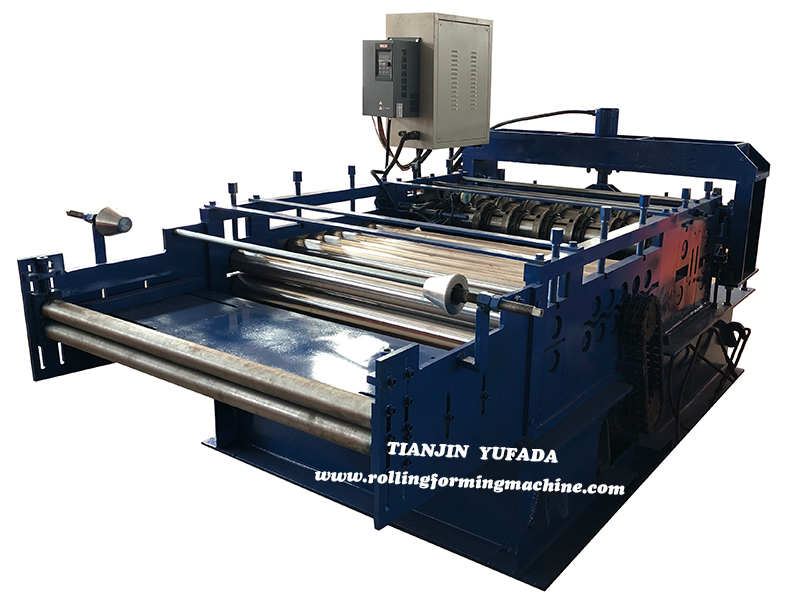

Description of 2000mm width 1.5mm thickness slitting machine with high quality

Automatic steel coil piece to piece sheet cutting machine line is using in wholesale sheet business. We use this machine to cut to pieces and sell them to client. This cutting machine can cut length one by one.

There are up 5 and down 6 stations for flatten the material which make coil straightly input to cutting machine. It is using for bring the steel coil running and do not break the surface of steel coil.

Some clients but piece to piece cutting machine for barrel galvanized corrugated sheet roll forming machine. And popular length are 8ft/10ft and 12 ft. Because if they pieces from the steel coil factory, price is very high. So they buy cutting machine for themselves. They can cut any length of roof panel what they need.

Capacity of cutting machine: the normal speed is same with the roof tile roll forming machine. So 8-12m/min. If you need this speed, you can use manual decoiler. If you wanted high speed, machine price will be added and you must choose electric decoiler or hydraulic decoiler. Because the speed is so that that the shaft can not bring the steel coil very well. So the length is not correct.

If you want to know more details of cutting machine, contact us directly.

Remark: if your need other thickness, please check we other type cutting machine

Machine parameters of 2000mm width 1.5mm thickness slitting machine with high quality

|

NO |

Type |

Specification | |

|

1 |

Raw material | Type | PPGI |

| Material width | 2000 mm or customize | ||

| Thickness | 0.3-1.5 mm | ||

|

2 |

Main body | Roller station | Up 5 down 6 row |

| Diameter of shaft | 70 mm | ||

| Shaft material | 45# with 0.05mm chrome | ||

| Roller material | 45# with 0.05mm chrome | ||

| Type | Chinese type | ||

| Frame | 300mm C-beam | ||

| Frame thickness | 16 mm | ||

| Material | Cr 12 | ||

| Operation | Hydraulic automatic | ||

| Working speed | 8-15 m/min | ||

|

3 |

Power | Driving way | 1 inch chain |

| Main motor | 5.5 KW | ||

| Voltage | 380V/50HZ, 3 phase | ||

1 Q: Are you a manufacturer?

A:Yes, we are manufacture with four branches factory

2. Q: How to order my machine

A: Send me your design drawing if you have.

Or tell me your design idea. Our engineer will design it as your needs.

3. Q: What details of the machine you should get from me.

A: I will confirm all details with you, such as the voltage in your city.

4. Q: I am new in this field. How could i understand the machine very well

A: Contact with us,24 hours online service side.

5. Q: I receive a lot of quotations, they are big difference, How could i choose?

A:we have many easy ways to solve it. Fox example, we can teach you how to find the Traders out. Just contact us.

6.Q: Can you give me one suggestion for ordering the machine.

A: No problem. Do not trust your eyes when you see beautiful pictures of machines or factories. More when you contact.

7. Q: Can you use other brand of spare parts for me if i want.

A: No problem if you want to pay the money.